Introduction of Driving Disc Plows

Driving Disc Plow has seen its emergence and improvement since the 1980s. It combines both the advantages of disc harrow and driving tools,which is good for saving energy, strengthening tractor’s power performance, guaranteeing perfect cultivation condition and satisfying various agricultural requirements.

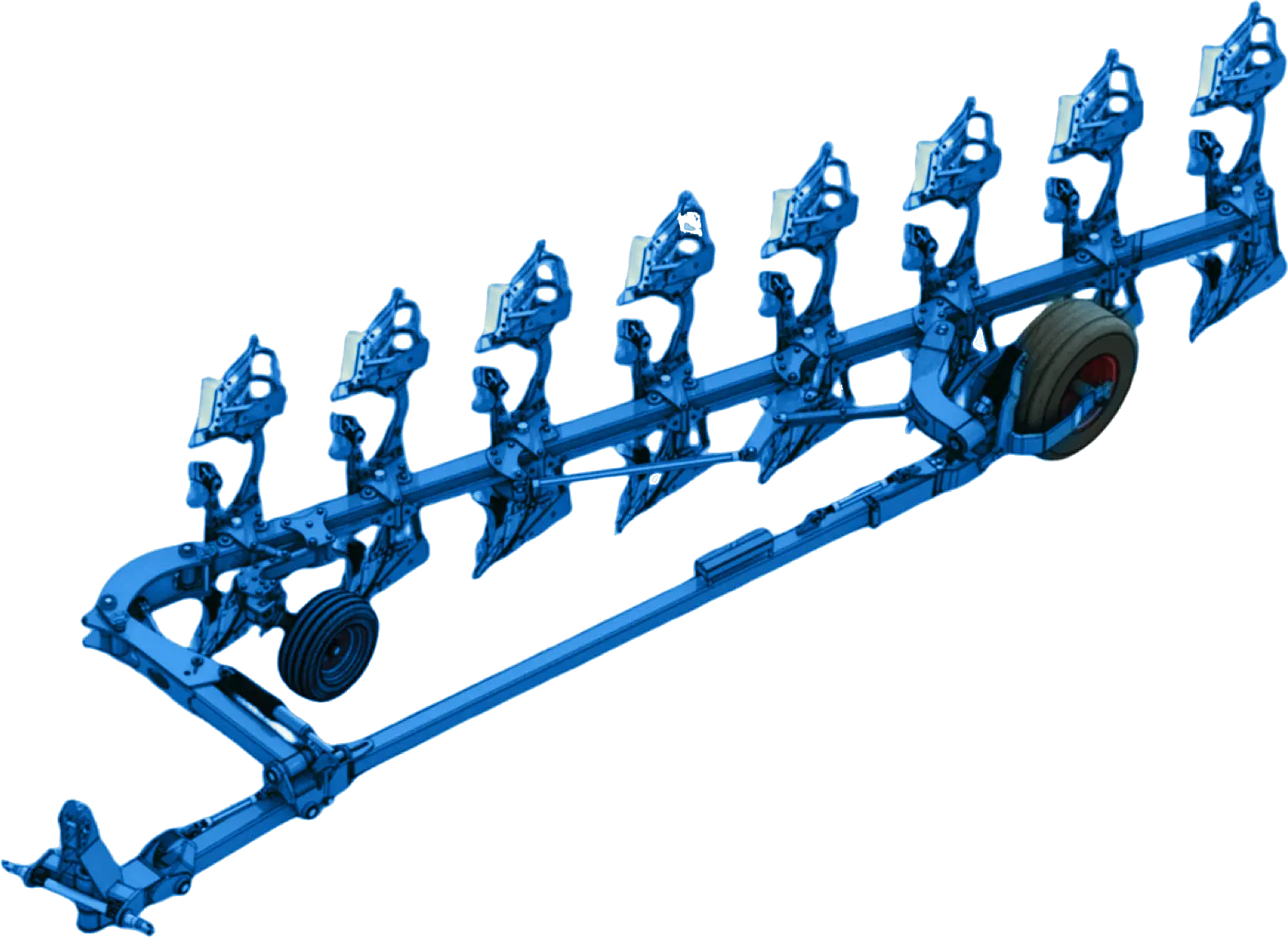

Demeter series driving dis plow is born on such basis. It takes three-point suspension and side mounted gear structure, which can be matched with 15-150 horsepower tractor. It is suitable for paddy, high yielding, green manure, grassy and upland field. Compared with traction-type tillage machine, it has good performance in walking on wetland, good climbing obstacle capability, low cost, etc.

Advantages of Driving Disc Plows

- Compared with other kinds of One Way Disc Plough or Reversible Disc Plough, the discs of this kind do rotation by themselves besides being driven forward by tractor. On the one hand, its own movement offsets part of the soil resistance, improving the utilization rate of tractor power; on the other hand, it slices the earth more easily and ensures the best soil condition for planting.

- The present research shows that under the same tractor and soil condition, driving disc plow can improve production efficiency by 25% and decrease fuel consumption over 15% per mu.

- It also has special superiority in straw returning on soil. When working, the rotating discs can cut down high stubble and cum successfully, and then overturn them to the bottom, improving soil fertility and soil constitution.

-

Warranty and Delivery of Driven Disc Plough

- Quality guarantee term is for one year. We will be responsible for the malfunctions which are caused by machine-self and quality. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be undertaken by customers.

- Delivery only takes about 15-20 days.

|

|

|

|

Technical parameters of Amisy series Driven Disc Plough

| Model | 1LYQ-320 | 1LYQ-420 | 1LYQ-520 | 1LYQ-522 | 1LYQ-622 | 1LYQ-722 | 1LYQ-822 |

|---|---|---|---|---|---|---|---|

| Matched power (hp) | 12~18 | 18~25 | 25~30 | 35~45 | 50~60 | 60~70 | 70~80 |

| Cultivating width (m) | 0.66 | 0.88 | 1.10 | 1.10 | 1.32 | 1.54 | 1.76 |

| Discs specification (mm) | 500*4 | 500*4 | 500*4 | 500*4 | 500*4 | 500*4 | 500*4 |

| Cultivating depth (mm) | 120~200 | 120~200 | 120~200 | 120~200 | 120~200 | 120~200 | 120~200 |

| Output speed (r/min) | 540/720 | 540/720 | 540/720 | 540/720 | 540/720 | 540/720 | 540/720 |

| Working speed (km/h) | 3~4 | 3~4 | 3~4 | 3~4 | 3~4 | 3~4 | 3~4 |

| Oil cost (kg/acre) | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 |

| Weigh (kg) | 216 | 240 | 276 | 300 | 321 | 357 | 410 |

| Linkage | three-point suspension | three-point suspension | three-point suspension | three-point suspension | three-point suspension | three-point suspension | three-point suspension |

| Outline dimension L×W×H (mm) | 855×1145×1050 | 965×1365×1050 | 1075×1585×1050 | 1075×1585×1050 | 1210×1805×1050 | 1325×2025×1050 | 1440×2245×1050 |

| Model |

1LYQ-922 1LYQ-922A 1LYQ-924 |

1LYQ-1022 1LYQ-1022A 1LYQ-1024 |

1LYQ-1122 1LYQ-1122A 1LYQ-1124 |

1LYQ-1222 1LYQ-1222A 1LYQ-1224 |

|---|---|---|---|---|

| Matched power (hp) | 90~100 | 90~120 | 100~120 | 100~150 |

| Cultivating width (m) | 2.10 | 2.50 | 2.90 | 3.30 |

| Discs specification (mm) | 560*4(560*5,610*5) | 560*4(560*5,610*5) | 560*4(560*5,610*5) | 560*4(560*5,610*5) |

| Cultivating depth (mm) | 160~200 | 160~200 | 160~200 | 160~200 |

| Output speed (r/min) | 540/720 | 540/720 | 540/720 | 540/720 |

| Working speed (km/h) | 3~4 | 3~4 | 3~4 | 3~4 |

| Oil cost (kg/acre) | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 | 0.60~0.75 |

| Weigh (kg) | 550 | 600 | 650 | 700 |

| Linkage | three-point suspension | three-point suspension | three-point suspension | three-point suspension |

| Outline dimension L×W×H (mm) | 1555×2630×1150 | 1670×2860×1150 | 1785×3090×1150 | 1900×3320×1150 |

Adjustable range of machines inclination angle: 28 ±5°

For any enquiries, please fill in contact form.

Thank you for your cooperation.