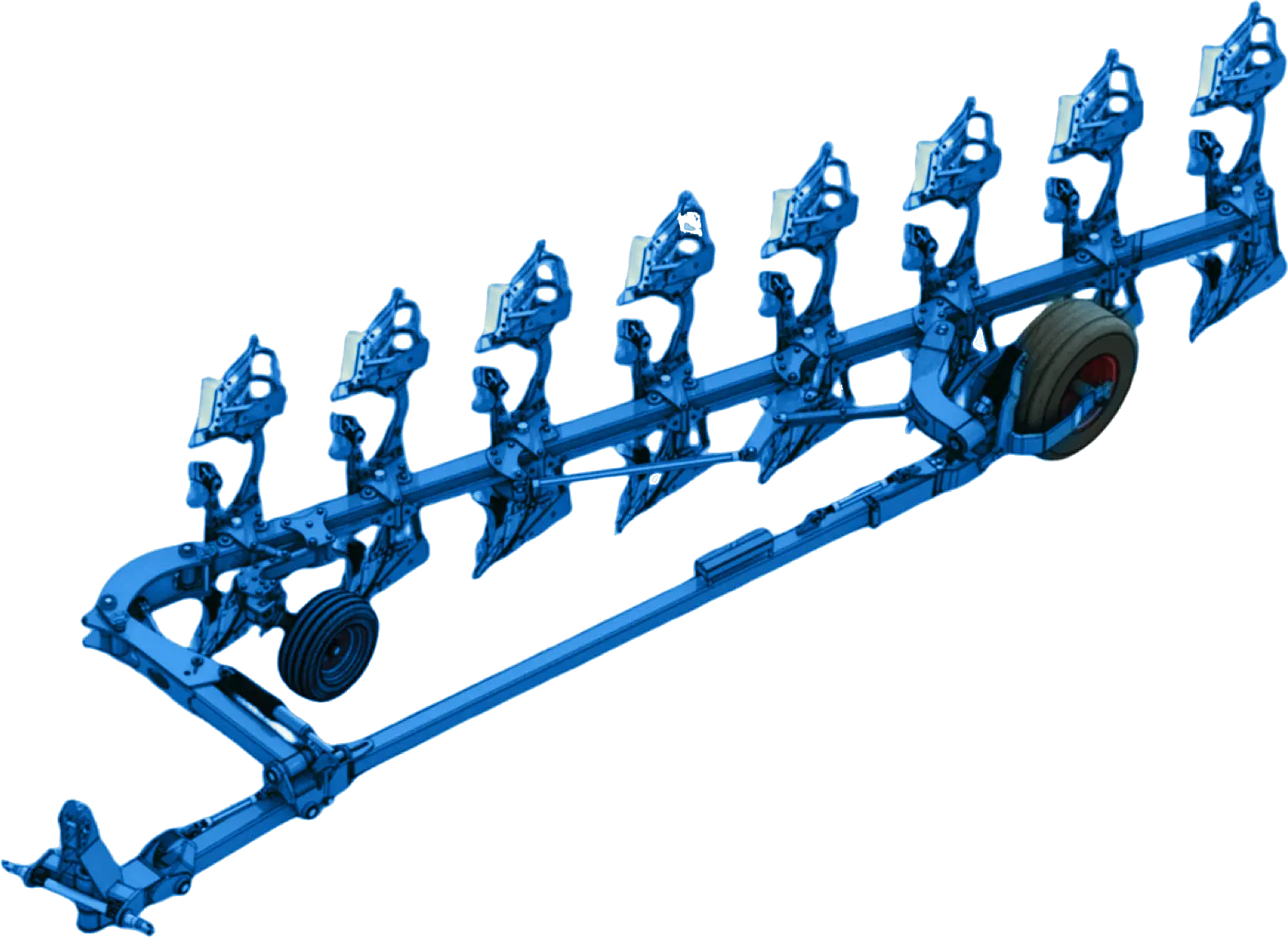

Semi-mounted Reversible plough

- For tractors from 300-450hp

- 6-8 furrows

- Body spacing 100 or 120cm

The semi-mounted reversible plough

Unlike fully mounted ploughs that attach directly to the tractor's three-point hitch, semi-mounted ploughs partially rest on their own wheel framework while still being connected to the tractor. This design allows for easier handling and maneuverability, especially in larger or heavier plough models, and is well-suited for medium to large-sized fields.

Key features and advantages

- Enhanced Maneuverability: The semi-mounted design ensures better ground following and adaptability to uneven terrain, leading to consistent soil cultivation.

- Adjustable Working Widths: Allows for customization to various soil conditions and field sizes, making the plough versatile for different agricultural needs.

- Reduced Tractor Wear: Distributes weight more evenly, leading to less strain on the tractor and lower maintenance costs.

- Improved Soil Health: Efficiently turns over soil, burying residues and promoting better water infiltration and aeration, which is beneficial for upcoming crops.

Core components

-

Main drive shafts employ specially treated spherical plain bearings, reinforced with heavy roll extrusion, resulting in significantly extended service life and more reliable functionality.

-

Incorporates a plough head constructed from robust alloy steel paired with a bidirectional steering cylinder, facilitating smooth directional changes and precise transitions.

-

The reversible plough beam is constructed using a special high tensile plate, ensuring enhanced strength and improved stability when switching working modes.

-

The redesigned reversible arm joint, made from a unique material, offers greater strength and a longer lifespan compared to traditional cast designs.

Structural Analysis

- 1&4. The front and rear tires are designed to automatically adjust their direction in accordance with changes in furrow width, significantly enhancing efficiency, especially in scenarios requiring frequent adjustments to the furrow width.

- 2. All pivoting joints are equipped with premium seals and feature imported, maintenance-free bearings, ensuring lifelong operation without the need for lubrication.

- 3. Adjusting the working width of each furrow is straightforward, with options for automatic hydraulic adjustments or semi-automatic adjustments using a specially designed turnbuckle.

- 1.The adjustable rotating plowshare can modify the distance between its turning center and the tractor's rear axle.

- 2.Both main and auxiliary plowshares are fitted with safety bolts to offer effective overload protection.

- 3.Dual locking safety pins ensure enhanced safety after transitioning between various operational modes.

- 4.The tractor's hitching point height can be easily and precisely adjusted using a screw buckle mechanism.

- 5.The amplitude of the plow can be automatically adjusted via the hydraulic system, or semi-automatically through custom-designed screw buckles, simplifying the operation.

- 6.The anti-blocking plowshare design prevents obstructions by film and stalks during use, ensuring greater efficiency and reduced energy usage.

- 7.All primary shafts employ high-precision spherical sliding bearings, providing exceptional longevity and reliability.

- 8.Special turnbuckles are employed for:

Below the ridge: Custom turnbuckles to set the working width.

Above the ridge: To adjust the gap between the tractor and the furrow edge.

Utilizing hydraulic cylinders instead of turnbuckles allows for adjustments directly from the driver’s seat, enhancing operational efficiency. - 9.The structural tilt can be modified using bolts located on either side.

- 10.A hydraulic mechanical depth adjustment is facilitated by a throttle valve.

- 11.The plow body, made from special high-strength alloy steel, ensures both the reliability and lightness of the machine.

Technical data semi-mounted reversible plough L10

| Model | L10/6+1 D100 | L10/7+1 D100 | L10/6+1 D120 |

|---|---|---|---|

| Plough bean size(mm) | 160*160*10 | 160*160*10 | 160*160*10 |

| Number of ploughshare | 6+1 | 7+1 | 6+1 |

| Spacing between ploughshare(cm) | 100 | 100 | 120 |

| Single plough working width(cm) | 33/50 | 33/50 | 40/60 |

| Height of the large plough(cm) | 180 | 180 | 190 |

| Weight(kg) | 3050 | 3500 | 3200 |

| Mathing power(hp) | 300-450 | 300-450 | 300-450 |

| Mathing power(kw) | 223-335 | 223-335 | 223-335 |

For any enquiries, please fill in contact form.

Thank you for your cooperation.