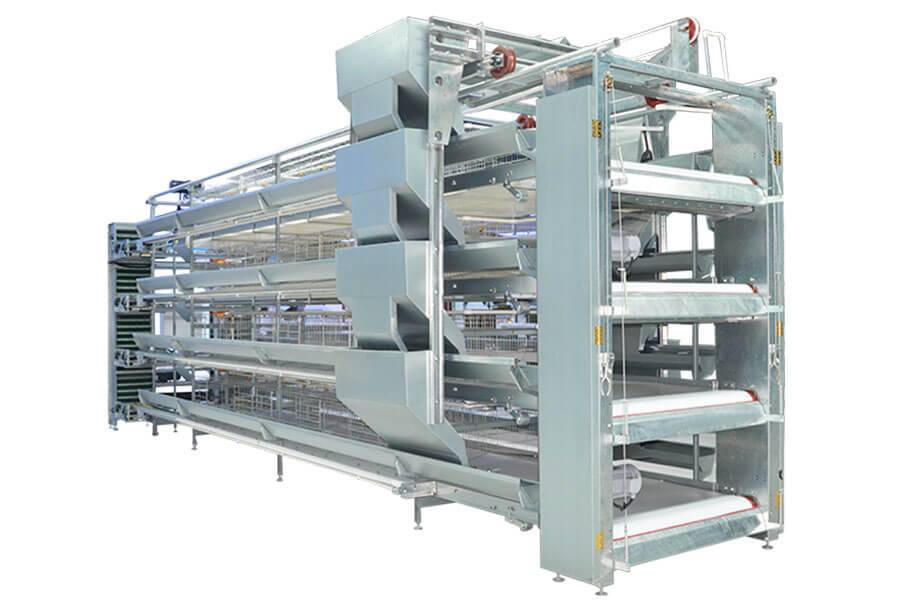

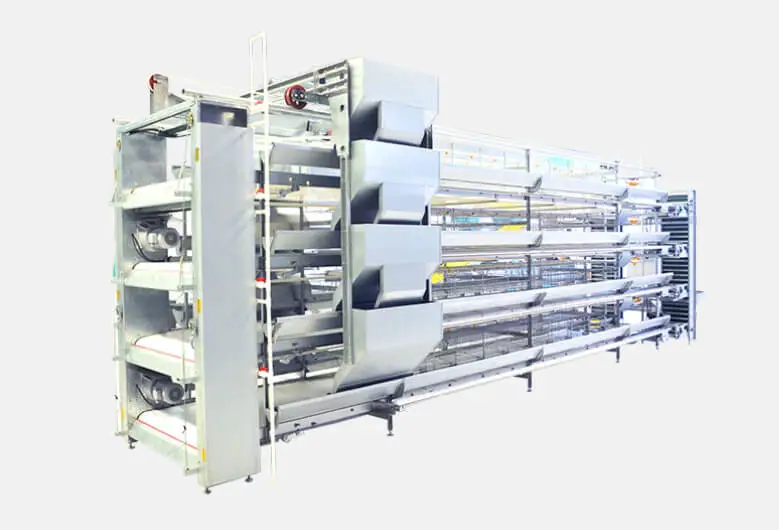

Full set of automatic layer chicken cage for sale adopt progressive plating process of electrostatic spraying, with the features of corrosion-resistant, and cages life can keep up to 15-20 years. You can operate it intensively and automatically in automatic poultry management system, which also make the layer feeding system, drinking system, poultry manure removal system, egg collection system coming into an automatic era, and improving manpower and saving labor costs greatly.

Poultry farming can achieve unprecedented scale of up to 10 high-density farming that can save land, and reduce construction investment and management costs, which are all suitable for enclosed house, automatic control of ventilation and temperature so that ensure the chicken coop environment more clean. It is easy to deliver and install for clients farming and making maintenance.

-

Features of H Type Layer Chicken Cage

- No waste of feed, save feed cost.

- Reasonable design and excellent ventilation.

- The sufficient drinking guarantee.

The full set of equipment using hot-dip galvanized material, corrosion-resistant, which ensures the service life of 15-20 years.

Intensive management and automated control. Achieve automatic feeding,drinking,manure cleaning,egg collecting and environment control,can help to improve working efficiency and save labor cost.

High-density raising,saves land and investment.

Suitable for closed chicken house. Automatic control of ventilation and temperature can meet the requirement of the birds.

In a house of 100m*13m, if 4 tier cages are installed, 39 units of cage per line, the height of side wall should be 4m, and total birds quantity is 37440; if 5 tier cages are installed, 39 units of cage per line, the height of side wall should be 4.5m, and total birds quantity is 46800; if 6 tier cages are installed, 39 units of cage per line, the height of side wall should be 5.0m, and total birds quantity is 56160.

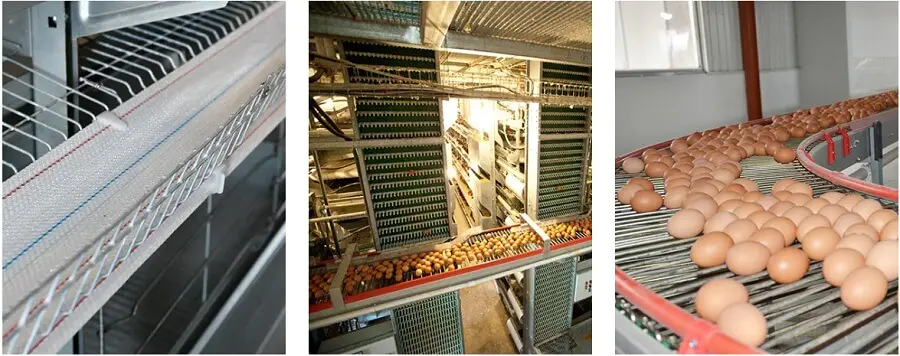

The new multi-tier large layer equipment with large cage position adopt narrow bottom and and large slope trough, which helps bird’s intake of feed and save feed.

The colony area per bird is 494 cm² and one cell can hold 17 birds. The increase of tier distance is beneficial to ventilation and light,it can avoid the occurrence of coccidiosis. The birds live more comfortablely with more space,is conducive to the healthy growth of chickens.

The number of units of automatic layer chicken cage can vary according to your necessity. Farmers need to get one starter for every row of cages. And the cage must need to be minimum 1 meter away from the wall to keep good humidity and air circulation. Then you need to install a large number of system with a roof tank to feed water to the birds inside the layer cage.

Automatic Egg Collection

The egg collecton system directly transport eggs into the egg storage. It raise the working efficiency and reduces the labor cost and percentage of egg broken.

Automatic Trolley Feeding System

The poultry feeding system include feed silo, automatic ladder type feeding system, feed troughs and so on.

Automatic Drinking System

The nipple drinking water system is useful, and the nipple drinker core is made of high-quality stainless steel. The water cup is also provided to ensure the chicken dung is dry.

Manure Clearing System

Each layer is transported by the longitudinal conveyor belt to the tail end of the chicken excrement. At the same time, the chicken coop is transported horizontally and is transported diagonally to a dedicated transport vehicle.

Smart Environment Control System

Technical data

| Model | 9CLD-3180 | 9CLD-4240 | 9CLD-5300 | 9CLD-6360 |

|---|---|---|---|---|

| Type | H | H | H | H |

| Size(L*W*H) mm | 2250*600*430 | 2250*600*430 | 2250*600*430 | 2250*600*430 |

| Doors/set | 5 | 5 | 5 | 5 |

| Birds/door | 6 | 6 | 6 | 6 |

| Capacity/set | 180 | 240 | 300 | 360 |

| Area/bird (cm2) | 450 | 450 | 450 | 450 |

| Cage width (m) | 1.7 | 1.7 | 1.7 | 1.7 |

| Manure belt width (m) | 1.21 | 1.21 | 1.21 | 1.21 |

| Equipment height (m) | 2.57 | 3.22 | 3.87 | 4.52 |

| Side wall height (m) | 3.5 | 4 | 4.5 | 5 |

| Model | 9CLD-4272 | 9CLD-5340 | 9CLD-8544 | 9CLD-9612 | 9CLD-10680 |

|---|---|---|---|---|---|

| Type | H | H | H | H | H |

| Size(L*W*H) mm | 2400*700*640 | 2400*700*640 | 2400*700*640 | 2400*700*640 | 2400*700*640 |

| Doors/set | 2 | 2 | 2 | 2 | 2 |

| Birds/door | 17 | 17 | 17 | 17 | 17 |

| Capacity/set | 272 | 340 | 544 | 612 | 680 |

| Area/bird (cm2) | 494 | 494 | 494 | 494 | 494 |

| Cage width (m) | 1.71 | 1.71 | 1.71 | 1.71 | 1.71 |

| Manure belt width (m) | 1.21 | 1.21 | 1.21 | 1.21 | 1.21 |

| Equipment height (m) | 3.3 | 3.9 | 6.8 | 7.4 | 8.2 |

| Side wall height (m) | 4 | 4.6 | 8 | 8.5 | 9 |

According to customers’ different requirements,3 tiers-10 tiers battery cage can be provided.

For any enquiries, please fill in contact form.

Thank you for your cooperation.