Main Feed Delivery Line

(1) Main feeding system is a complete set of automatic feeding system, included a material conveying pipe, silo, auger, drive motor and a feed level sensor.

(2) Main feed line is mainly used to deliver feed from silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line, which can control the drive motor on and off to realize automatically feeding.

| Manpower hopper or silo | 600/800kg hopper, 5/8/10/15/18/20mt silo |

| Motor |

Power: 0.75Kw/1.1Kw Voltage: 380V, three-phase/220V, single-phase/others |

| Main feed line |

Diameter of pipe: 75mm Material: PVC |

| Auger | Feeding ability: 1400Kg/h (maximum) |

Automatic Pan Feeding Line System

| V-shape bin (with hopper) |

Bin volume: 100L Material: Hot-DIP galvanized sheet |

| Motor |

Power: 0.75Kw/1.1Kw/1.5Kw Voltage: 380V, three-phase/220V, single-phase/others |

| Delivery pipe |

Diameter of pipe: 45mm Material: Hot-DIP galvanized steel |

| Auger | Feeding ability: 450Kg/h (maximum) |

| Feed pan |

Pan distance: 4 pans/3m, 3 pans/3m Raising ability: 45-55 birds/PC Material: Pure engineering plastic |

| Suspension & lifting device | We can adjust the feeding line by winch. |

| Anti-perching device | It prevents birds staying on the feeding line for too long. |

Automatic Nipple Drinking Line System

This system can provide fresh and clean water for poultry which is crucial for the growth of Poultry.

The drinkers can be triggered from 360 degree which helps young birds start well and makes drinking easier.

| Waterline front system |

Filter Pressure regulating valve Water meter Medicator(doser) |

| Water pipe with nipple drinker and drip cup |

Nipple distance: 16 nipples/4m, 12 nipples/3m Raising ability: 8-12 birds/PC Nipple material: Inside valve is made of stainless Steel, shell is made of plastic Drip cup material: Pure engineering plastic |

| Suspension lifting device | We can adjust the drinking line by winch. |

| Waterline end module | Water display tube, etc |

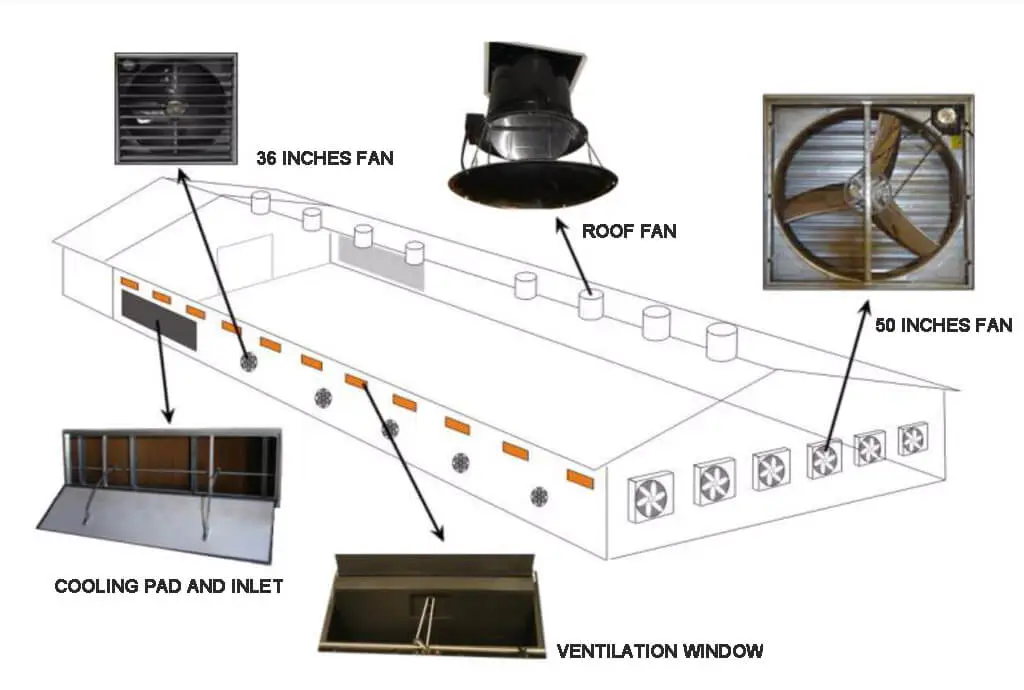

Automatic Ventilation Fan System

| Specifications | 50” box fan | 36” box fan |

| Flow amount (m³/h) | 41000 | 20800 |

| Size (L*W*H) (mm) | 1380*1380*450 | 1000*1000*450 |

| Noise level | ≤65dB | ≤64dB |

| Power | 1.1Kw | 0.4Kw |

| Voltage | 380V/220V/others | 380V/220V/others |

| Current | 2.8A | 1.6A |

| Weight | 88Kg | 66Kg |

The system controls climate condition, can provide fresh air, proper humidity and temperature for birds, ensuring your chickens provide maximum production.

The system including ventilation fan (box fan or butterfly cone fan) and air inlets.

If your chicken farm is open, there is no need to use 36” fan and air inlets, however, you might need curtain system.

Cooling Pad System

Thickness: 100mm; 150mm

Width: 600mm

Height(with frame): 1660mm; 1960mm; 2160mm

Frame: Galvanized sheet/Aluminium alloy

When the air goes through the pad, the heat will be took down by the evaporation of water, so the air will be cooled before going into the chicken farm.

-

Environment Control System

*The system saves labor and resources under the condition of assuring the optimum growth environment of chickens.

*It is imported from Israel can set an optimum working mode according to the local climate and raising environment.