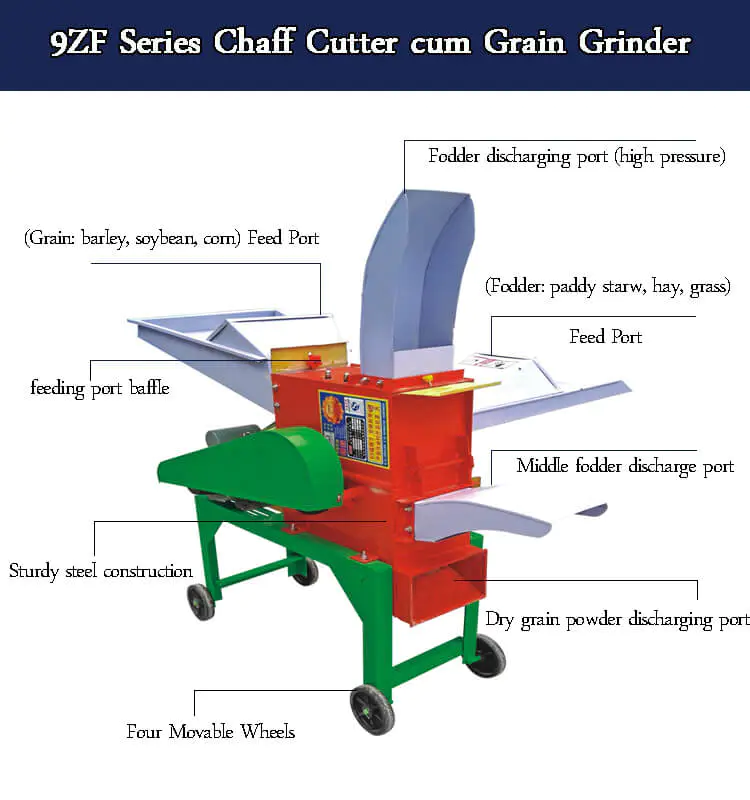

Chaff Cutter cum Grain Grinder Machine Introduction

This agricultural fodder chaff chopper machine is with multi-functions: silage fodder cutting and grain milling. On the one hand, it can cut paddy straw, hay, grass into small pieces for the dairy farms; on the other hand, it can grind barley, soybean, corn, potato, cassava, wheat, etc. That’s why we call it Chaff Cutter cum Grain Grinder.

One thing to be noticed is that the chaff cutter cannot achieve both cutting and grain milling simultaneously, it working separately with different feeding port and discharge port in the same machine frame.

Advantages of 9ZF Series Agricultural Chaff Cutter

- It is an economical and practical cutter and grinder machine. It not only can cut any grasses and straws but crush some granular crops. Thus, this chaff cutter and grinder machine is a good choice for some home users.

- The straws and grass are in high softness. The power of this machine adopts circular-arc blades. In this way, it saves power. This machine increases the sawtooth blades and mesh, panels in the crushing chamber.

- It has high efficiency. There are several production capacity models that can be chosen, 0.4 t/h, 0.6 t/h, 0.8t/h, respectively.

- It is of high quality and durable features. This machine allows you to customize according to your requirements, whatever in color or yield.

-

The fodder chaff chopper machine consists of hammers, screen pieces, rotors, feeding devices, and machine frames. The cutting process is completed in the crushing chamber in which rotors locate. The main working parts of the cutter machine are hammers and blades installed at rotor assembly.

In this cutter crusher machine, the main working parts are the blades and hammer installed at the rotor assembly. It has multiple functions, a simple structure, easy to install and operate, so it has become an economy and widely used chaff cutter and crusher machine for home users.

-

Chaff Cutter and Grinder Working Principle

When the machine begins to work, raw materials are sent to the crushing chamber through the feeding hopper and shattered by the high-speed rotating working parts. At the same time, the moving direction of raw materials is changed. Because the high-speed rotating working parts destroy the deposition of the material layer, the raw material moves with the rotor. In this process, the grass or the granular collides or rubs with each other so that it is crushed into smaller sizes than mesh diameter. Under the influence of centrifugal force and airflow, the processed material is discharged through the mesh to the powder room, and the cutting grasses can be sprayed from the high spout.

The particle size is determined by the screen size. You can choose a suitable mesh according to feed or grain granularity. Hammer is wearing part so users should check worn condition frequently. When one corner of the hammer is worn out, you can turn and use it, but the mounted position and hammer can’t be changed casually, avoiding affecting rotor balance.

Chaff Cutter and Grinder Application Range

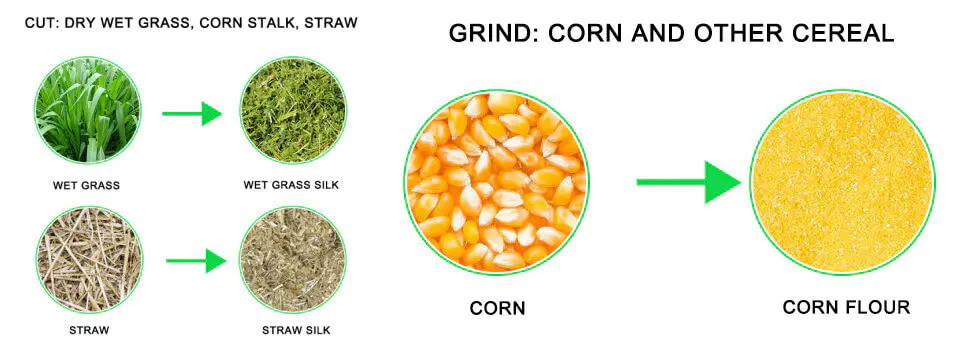

Cutting application: all kinds of wet and dry grass and straws, like cured hay, green grass, dry and wet cornstalk, bean straw, what straw, etc.

Grinding application: different granular grains, like corn, soybean, wheat, soybean meal, etc.

Fodder Chaff Chopper Technical Data

|

Model

|

9ZF-400-12

|

9ZF-400-20C

|

9ZF-400-24C

|

9ZF-400-24B

|

9ZF-400-30

|

|---|---|---|---|---|---|

|

Dimensions(mm)

|

650*340*830

|

850*1310*1400

|

850*1350*1440

|

1180*1090*1040

|

1220*1150*1040

|

|

Weight(kg)

|

60kg

|

55kg

|

70kg

|

70kg

|

80 kg

|

|

main shaft speed(r/min)

|

3500r/min

|

3100r/min

|

3100r/min

|

3100r/min

|

3100r/min

|

|

Power

|

2.2-3kW

|

2.2-3kW

|

2.2-3kW

|

2.2-3kW

|

2.2-3kW

|

|

Rotor diameter

|

390mm

|

360mm

|

360mm

|

360mm

|

360mm

|

|

Amount of Hammer

|

3 Groups(4pieces in each group)

|

4 groups

(4pieces in each group)

|

4 groups

(6pieces in each group)

|

4 groups

(6pieces in each group)

|

4 groups

(6or 8 pieces in each group)

|

|

Sieve diameter

|

3.0mm

|

3.0mm

|

3.0mm

|

3.0mm

|

3.0mm

|

|

Capacity(kg/h)

|

>200-600kg/h

|

>200-400kg/h

|

>400-600kg/h

|

>400-600kg/h

|

>600-800kg/h

|

For any enquiries, please fill in contact form.

Thank you for your cooperation.