Introduction of 9ZP Series Chaff Cutter

9ZP series chaff cutter is the latest Fodder Cutting Machine, selling very well at home and abroad. 9ZP series chaff cutter can be divided into 2 types in accordance with its feeding system: manual feeding types and automatic feeding ones (belt conveying system is installed). Manual feeding straw shredder machine includes 3 models (varies with production capacity): 9ZP-1.5T, 9ZP-1.8T, 9ZP-3T.

Manual Feeding Paddy Straw Shredder Highlights

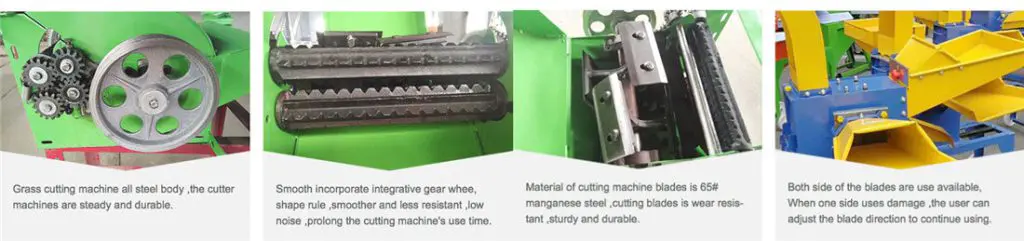

- The whole rack is a steel structure, which is durable. The structure is simple, easy to take apart and install.

- This frame adopts the combination of cast iron and steel plates to enhance the stability of the work and reduce the noise.

- The transmission shaft adopts the universal joint, which is compact and flexible.

- The blades are made of high-quality steel, more wearable. Adopts high strength bolts, which has advantages of safety and reliability in performance.

- Safe and reliable. This machine adopts a protective device.

- Various mating power. Motors, diesel engines, and tractors can be used as the power,suitable for some areas lacking electricity.

Application of Manual Feeding Straw Cutter

It is mainly used to cut the green (dry) corn straw, rice straw, wheat stalk, grass, etc. It’s a kind of agriculture forage feed processing machine. It suits to feed the cattle, sheep, horse, deer and other animals. Manual feeding straw chopping machine has the advantage of small size, light-weight, and high efficiency, which makes it a good helper for the farmers to cut the grass in small and medium-scaled poultry farms.

According to different outputs, customers can choose different models. We provide 1.5T/h, 1.8T/h, and 3T/h three types of chaff cutter for customers. Furthermore, these chaff cutters can be customized in different colors as needed.

Working Principle of Manual Feeding Straw Shredder Machine

The motor is the mating power. The machine transfers the power to the main shaft; the gear at the end of the main conveys the power to the pressure roller through the gearbox and universal joint. When the materials came into the upper nip roller and lower nip roller, they are sent to the cutting structure, which is rotating with high speed. Finally, the materials are chopped and spouted from the outlet.

Components of Manual Feeding Chaff Cutter

It mainly consists of a feeding structure, cutting structure, transmission structure, moving structure and protection structure, etc.

- Feeding structure: it mainly includes the feeding hopper, fixed blades, and bracket.

- Cutting structure: blades, cutter, and lock screw constitute the cutting structure.

- Transmission structure: it is made up of the triangle belt, transmission shaft, gear, and universal joint.

- Moving Structure: the machine is furnished with 4 wheels, which is convenient for users to move.

- Protection device: cover is the main protective device, which highly enhances security.

Daily Maintenance of Manual Feeding Rice Straw Chopper Machine

- ◆ Check the fastening conditions of the parts regularly. Prevent the fall of parts and breakdown of the machine.

- ◆ Each oil filler hole should be injected frequently, and the bearings are poured into calcium base grease in six months.

- ◆ When the machine stops working, idle for a while to remove the dust and weeds. Finally, turn off the chaff cutter.

- ◆ When the chaff cutter is out of work, which should be placed in a warehouse with dry air and no corrosive gas. Besides that, inject lubricating grease to all rotating parts.

Technical Data of Manual Feeding Type Chaff Cutter

|

Model

|

9ZP-1.5T

|

9ZP-1.8T

|

9ZP-3T

|

|---|---|---|---|

|

Matched power (KW)

|

2.2-3

|

2.2-3

|

4

|

|

Matched voltage (v)

|

380

|

380

|

380

|

|

Capacity (t/h)

|

1.5

|

1.8

|

3

|

For any enquiries, please fill in contact form.

Thank you for your cooperation.